The Project

Oosterhorn Green Hydrogen (also known by project name ‘Broadway’) consists of a modular electrolysis plant with an expected capacity of 20 MW. This will produce green hydrogen to make local industry and mobility more sustainable. The hydrogen produced is of the highest purity, making it suitable for multiple applications (transport, combustion, feedstock).

The produced hydrogen will be transported to local customers via a yet-to-be-constructed hydrogen pipeline. As the hydrogen is transported directly to the customers, no high-pressure storage is planned on site for the time being.

To minimise congestion on the electricity grid, efforts will be made to connect directly to local wind and/or solar farms.

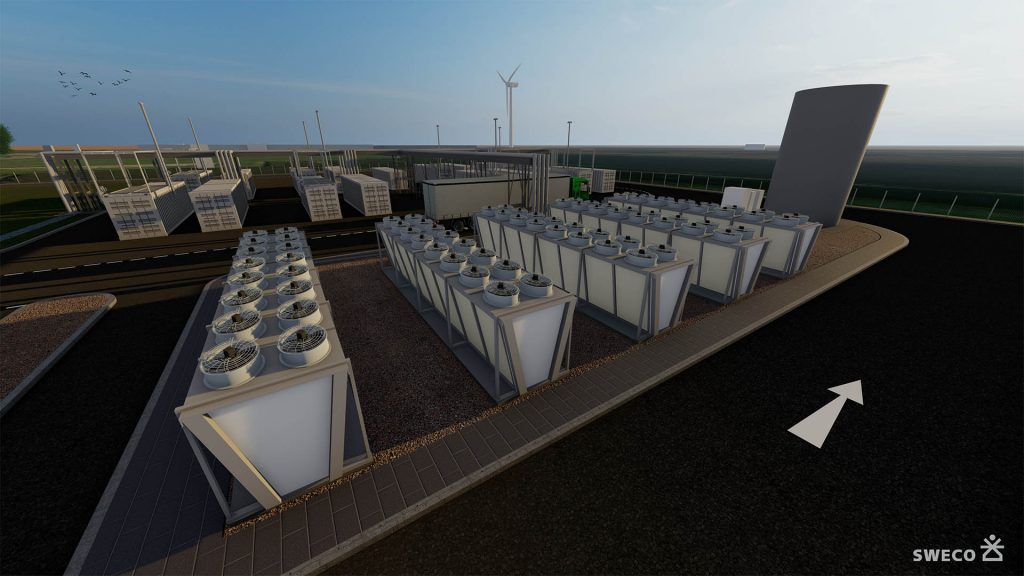

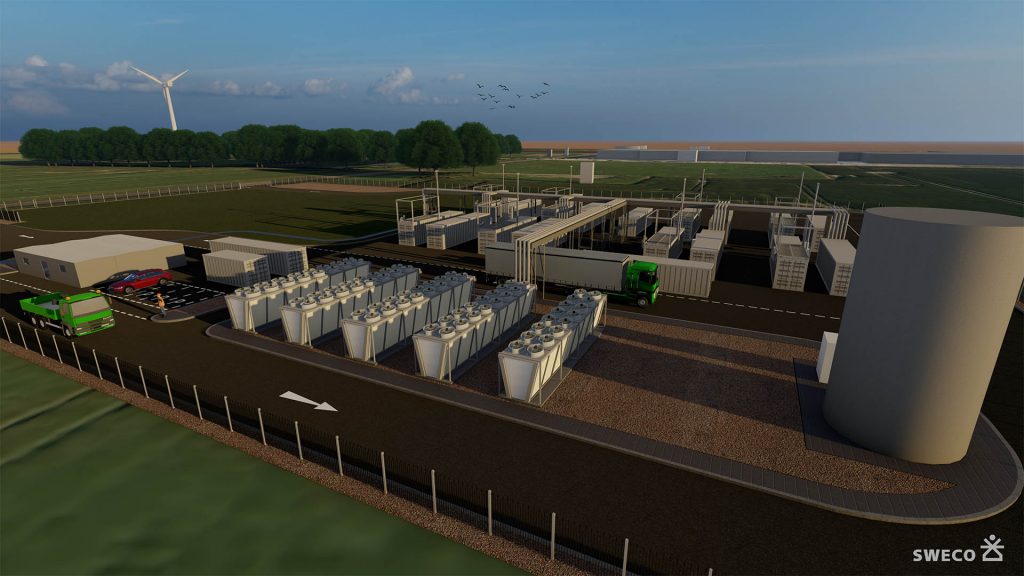

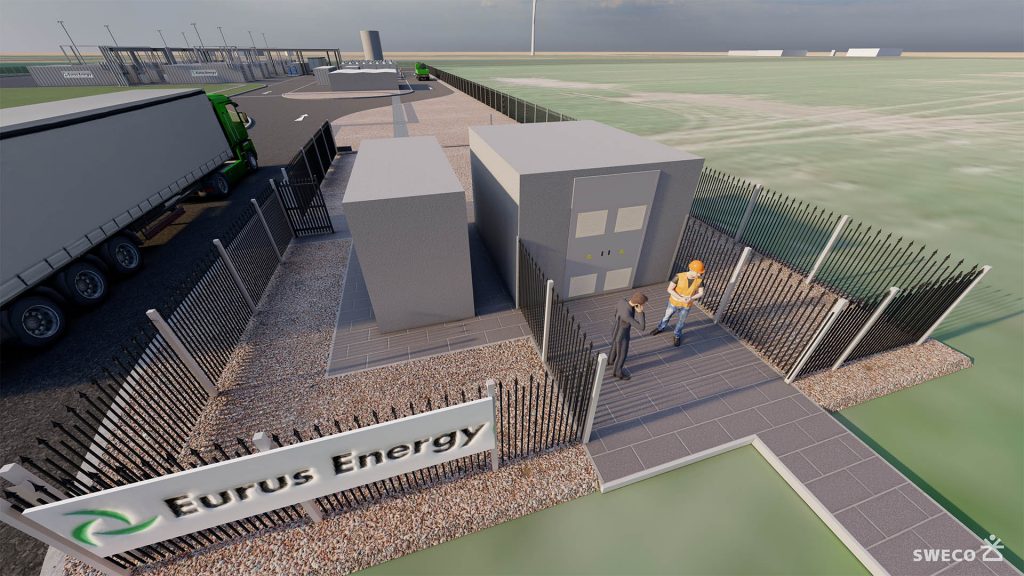

Impression

Location

Oosterhorn Hydrogen will be constructed on Kloosterlaan in the port area of Delfzijl, close to potential customers and wind farm Oosterhorn in the chemical park. There are several (green) hydrogen producers and customers in this cluster which can be directly connected.

Effects on the environment

The impact on the environment is minimal, as the project site is in the middle of the Oosterhorn industrial area, and there are no harmful emissions. Raw materials are (demi-)water and green electricity, and the (residual) product besides hydrogen is oxygen. The plant meets current noise and environmental standards.

Permit

The Province of Groningen has published a draft decision on the requested WABO and building permit for the Project on June 12th 2023.

Technical specifications

The plant will have a capacity of 20 MW, producing up to 360 kg per hour (4,000 NM3/h) of hydrogen. Delivery will take place at around 28 bar(g) via a direct pipeline to the customer.

The electrolyzers are PEM (Proton Exchange Membrane) electrolyzers, which have as advantage that they are more compact, and do not contain or use harmful substances in the process of making hydrogen. The electrolyzers are built in shipping containers and include water purification steps and all remaining electronics required to produce hydrogen in addition to electrolysis ‘stacks’.

Timeline and planning

- Final investment decision (FID): 2024

- Commercial operation date: 2025